With his permission i'm reproducing some of the translations here, minus the pictures.. hopefully the text alone can offer some information/knowledge

Translated Articles from Early Teapots Volume 2 早期壶事典-貳

Hello folks, as you know the past year there was a great book published by Dr Lv Qi Lin (taiwan) on Shuiping teapots and I was involved with the english translation of it.

With his permission i'm reproducing some of the translations here, minus the pictures.. hopefully the text alone can offer some information/knowledge I may also copy some of the translations of his writings onto thread for public knowledge.

I may also copy some of the translations of his writings onto thread for public knowledge.

With his permission i'm reproducing some of the translations here, minus the pictures.. hopefully the text alone can offer some information/knowledge

Apr 8th, '17, 09:37

Posts: 1144

Joined: Jul 10th, '13, 01:38

Scrolling: scrolling

Location: Japan.

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

Amazing opportunity for all of us .. thank you KZ for all your efforts, much appreciated!!kyarazen wrote: Hello folks, as you know the past year there was a great book published by Dr Lv Qi Lin (taiwan) on Shuiping teapots and I was involved with the english translation of it.

With his permission i'm reproducing some of the translations here, minus the pictures.. hopefully the text alone can offer some information/knowledgeI may also copy some of the translations of his writings onto thread for public knowledge.

Can't wait to read some of this material!!

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

Lets start with some of the Terminologies :

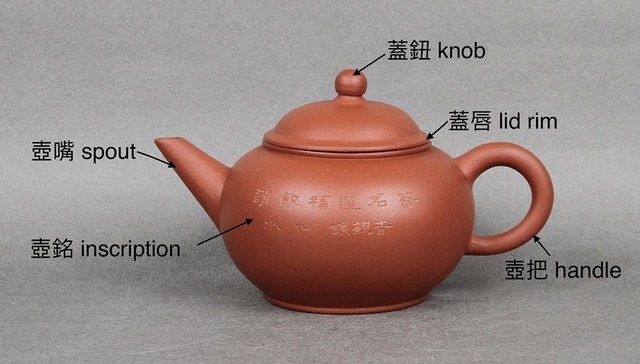

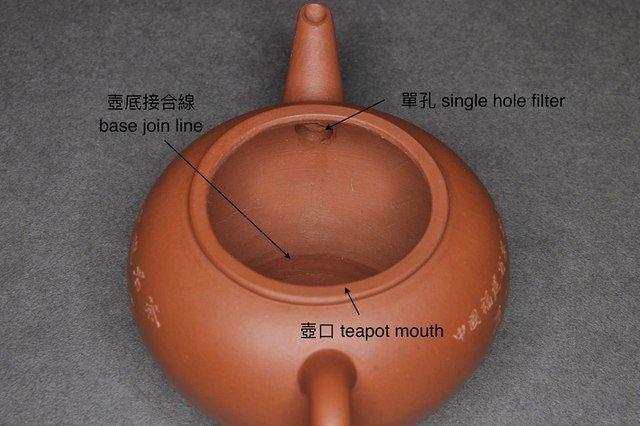

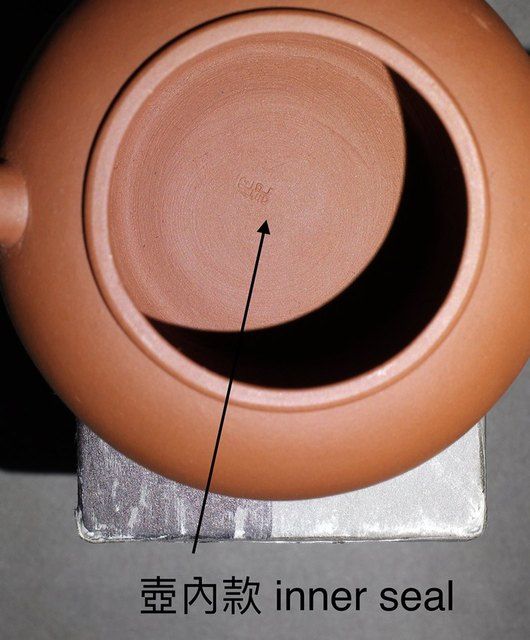

早期壺中英文術語/Chinese-English Early-period Teapot terminology

早期壺事典的翻譯工作己經展開,因為之前相關的文獻十分少,為了使大家在討論上有一個共通的語言,日後我們將會把翻譯過程中所定義的專有名詞陸續補充在這一帖中,以提供大家在討論時有一個共同的術語基礎。當然我們也很樂意聽取大家的意見,希望能一起為早期壺建立一個大家所接受的國際性共通語言。謝謝大家。

The translation of Early period teapot Encyclopedia has been started. Because the relative literature is few, for the purpose to have a common terminology for discussing, we decided to post the terminology we defined in the following process of translation. Of course, we would like to hear your opinions and hope we can construct an international common terminology for Early Period Teapots, which is worldwide acceptable. Thank you.

目前我們已定義的有:

So far we already defined including:

早期壺 Early-period teapot

宜興一廠 Yixing Factory #1

標準壺/水平壺 Shuiping

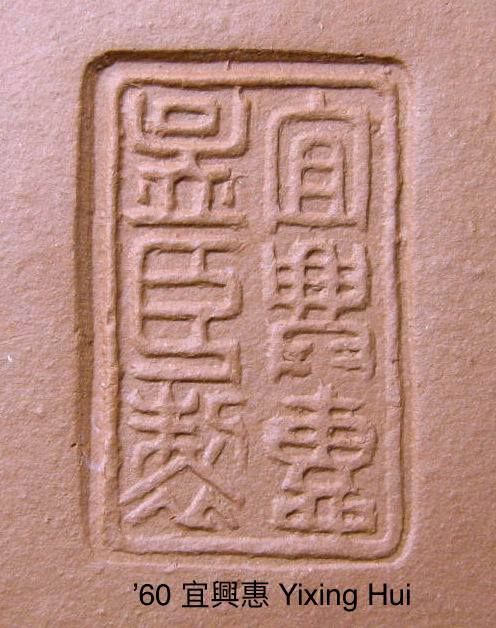

60年代印款中的:

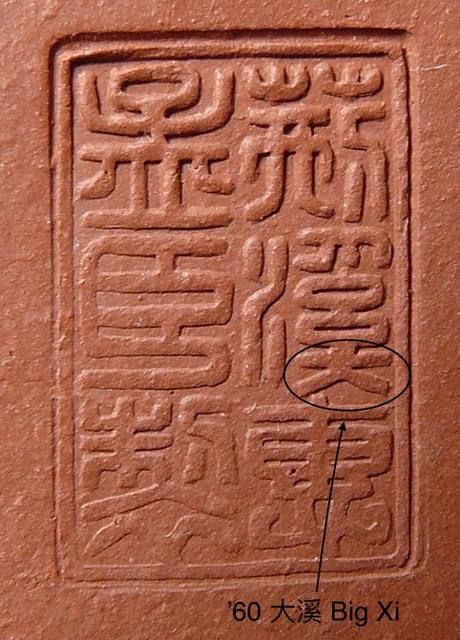

大溪 Big Xi/Da Xi (please see the attached picture)

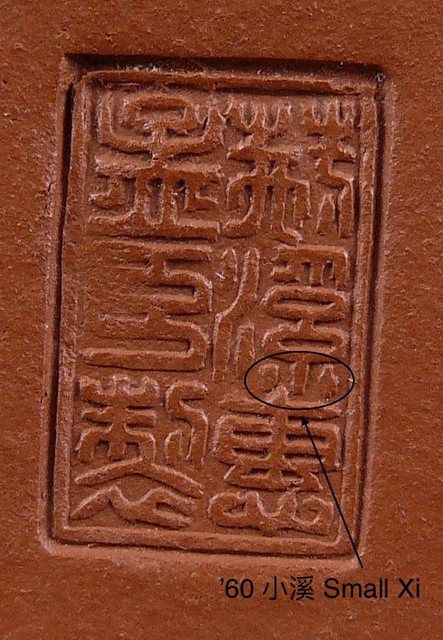

小溪 Small Xi/Xiao Xi (please see the attached picture)

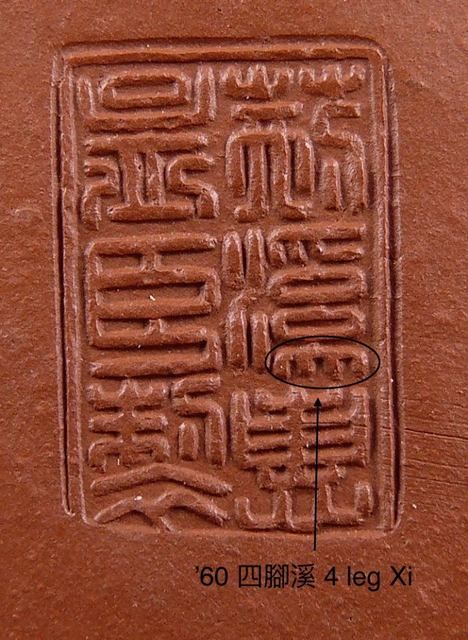

四腳溪 4 leg Xi (please see the attached picture)

荊溪惠孟臣製 Jing Xi Hui Meng Chen zhi

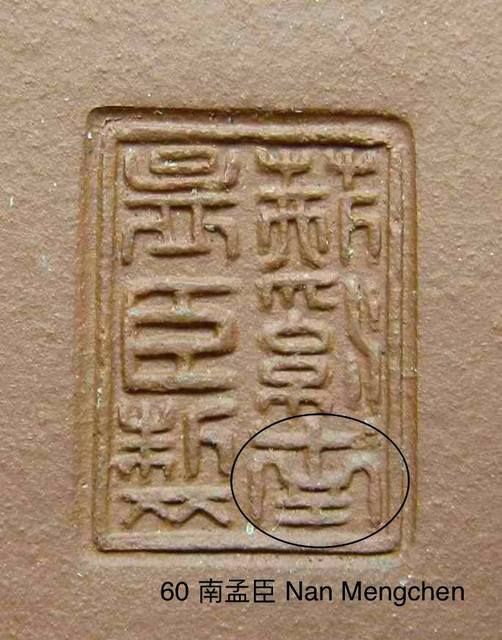

南孟臣 Nan Meng Chen

宜興惠 Yi Xing Hui

庭記 Ting Ji

熙生 Xi Sheng

清末 late Qing

清末民國初時期 Qing-ROC period

龍窯 dragon kiln

五形壺 5 shapes teapots

亂六字款 massy 6 character seal

倒焰窯 downdraft kiln

注漿法 slip-casting

待續... To be continued...

早期壺中英文術語/Chinese-English Early-period Teapot terminology

早期壺事典的翻譯工作己經展開,因為之前相關的文獻十分少,為了使大家在討論上有一個共通的語言,日後我們將會把翻譯過程中所定義的專有名詞陸續補充在這一帖中,以提供大家在討論時有一個共同的術語基礎。當然我們也很樂意聽取大家的意見,希望能一起為早期壺建立一個大家所接受的國際性共通語言。謝謝大家。

The translation of Early period teapot Encyclopedia has been started. Because the relative literature is few, for the purpose to have a common terminology for discussing, we decided to post the terminology we defined in the following process of translation. Of course, we would like to hear your opinions and hope we can construct an international common terminology for Early Period Teapots, which is worldwide acceptable. Thank you.

目前我們已定義的有:

So far we already defined including:

早期壺 Early-period teapot

宜興一廠 Yixing Factory #1

標準壺/水平壺 Shuiping

60年代印款中的:

大溪 Big Xi/Da Xi (please see the attached picture)

小溪 Small Xi/Xiao Xi (please see the attached picture)

四腳溪 4 leg Xi (please see the attached picture)

荊溪惠孟臣製 Jing Xi Hui Meng Chen zhi

南孟臣 Nan Meng Chen

宜興惠 Yi Xing Hui

庭記 Ting Ji

熙生 Xi Sheng

清末 late Qing

清末民國初時期 Qing-ROC period

龍窯 dragon kiln

五形壺 5 shapes teapots

亂六字款 massy 6 character seal

倒焰窯 downdraft kiln

注漿法 slip-casting

待續... To be continued...

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

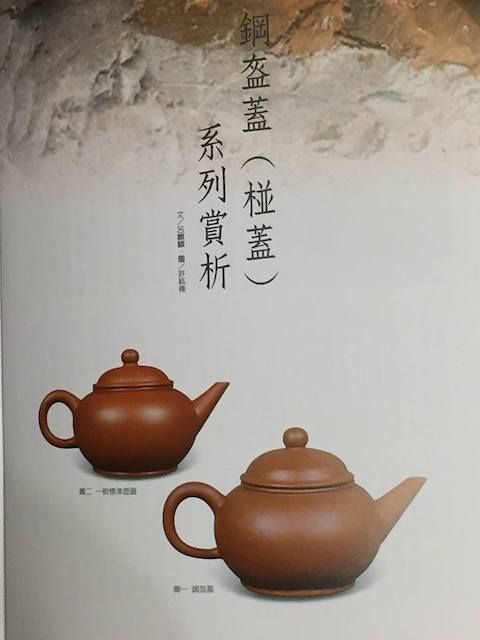

Chapter 2 - the Puff Lid / Helmet Series

Chapter 2 The “Helmet Lid” (“Puffed Lid”) Teapot Series

(draft version)

(鋼盔蓋(椪蓋)系列英文版初稿)

(Please match this article with the content of P.18 to 25 of my book to read.)

After the establishment of Yixing Factory #1, all pots are produced in a very systematic way, and there is plenty of evidence for us to trace. Pots made during different time periods and in different environments will show characteristics of these periods. These characteristics and systems are not only important tools of us to grasp early-period teapots but also represent some part of Yixing zisha history.

The early-period teapots express the phrase “from diversity to unity”. If we want to fully understand this development and importance, we need to pay attention to the earliest examples of early-period teapots, the “helmet lid” / “puffed lid” series.

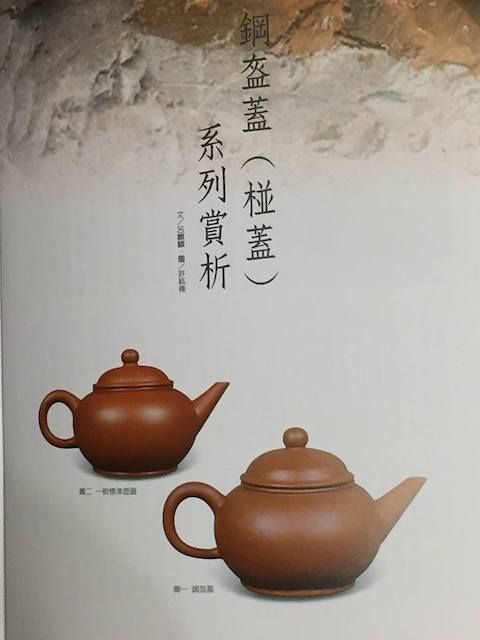

What we call “helmet lid” (鋼盔蓋; gāngkuī gài; steel helmet lid) or “puffed lid” (椪蓋; pèng gài), refers to the shape of the pot lid, where the curve from the edge of lid towards the knob rises more sharply, resulting in a more convex shape, reminiscent of a military helmet. Figures 1 and 2, show the differences in shape between the helmet lid and the regular 1970s shuiping teapot lid. The helmet lid looks as though it is half of a sphere, whilst the 70s lid is generally flatter. The lid is not the only unique attribute of this series; rather, the “helmet lid” series has other important differences from other early-period teapots, including age, workmanship, clay, firing and era meanings. We will discuss these attributes in the following paragraphs.

If we want to explain the period of the helmet lid, we need to first understand how pot lids are made. Early-period teapot lids were made in two different way. The first method involved putting a piece of flattened clay into a steel or plaster mold, and pressing to form the basic shape, then detailing by hand. The earlier the pot was produced, the less prevalent the use of molds, so the signs of handmade workmanship are more obvious. For example, the method of joining the lid wall to the lid by hand is a method inherited from Qing in the early ROC period, until the end of the 1950s, where the lid walls were made by mold together with lid, (see p.514 for reference). In the second method, the lids were completely handmade. Regardless of the method used, the curvature of the lid is determined by the shape and curvature of the mold, which, in turn, was determined by the aesthetics and common practice of ceramic artists during that era. As such, the curvature of the lid evolved over time.

Let us start by examining a zhuni (朱泥; zhūní; vermillion) shuiping pot made in the late Qing / early ROC era, stamped with the Xi Sheng (熙生; xīshēng) seal (refer to figure 3). This is an authentic piece of Qing to ROC handmade shuiping pot, not only is the clay texture very delicate, but the workmanship is also very detailed. The lid walls, instead of being rounded, are beveled inwards, a mark of a pot made by a master craftsman. This pot shape and workmanship is similarly seen in works by other famous Qing potters, e.g., Chang Ji (昌記; Chāng Jì), Yuan Yi He (袁義和; Yuán Yì hé), so we can conclude that many of the shuiping pots with similar marks can classified as the platonic ideal of a shuiping pot. From the shape of the lid of this pot, we can see that during the late Qing period, the standard style for shuiping lids is the rotund “helmet lid”. This style was the standard through early ROC, even the early years of Factory #1 in the late ‘50s. We can still find examples of this style in the early ‘60s, but in much smaller quantities. In figure 4, you can see a 1960s six cup shuiping pot; the base seal is 6 characters, and the inner base seal is Ting Ji (庭記; tíng jì), this represents the last appearances of the helmet lid in Factory #1. (Note: not all of the Ting Ji pots have helmet lids). After the mid ‘60s, due to new molds, the helmet lids were replaced with flatter lids, and as such, the helmet lid style became more or less extinct after that time.

Why were the molds changed from the “helmet lid” shape to the comparatively flatter design? It could be due to the emphasis on productivity and high volume during that time period, because the helmet lids were harder to remove from a mold than the flatter ones were, or it could simply be a change in style / aesthetics. However, this shape only appeared between the end of the Qing period to the early ‘60s. This characteristic was not seen in pots from the later years. As we discuss the helmet lid teapots, this term refers not just to the shape of the lid, but also to a specific era.

The seals and workmanship of helmet lid pots

From the seals and workmanship of helmet lid pots, we have now identified that this characteristic spans the late Qing to the early 1960s. Within this timeline, there is a very important landmark — the establishment of Factory #1. Before Yixing Zisha Factory #1 was established, pots were mostly made in private workshops by artisans; the seals used were diverse, the pots were largely handmade — the seam of the lid wall, the body, the spout, and the handle were mostly handmade. In contrast, after the establishment of Yixing Factory #1, because of the shift towards mass production, previously handmade parts were now also shaped by molds; most items were initially formed using molds, and then finished by hand. Naturally, the pots produced after the establishment of Factory #1 used the standard “6 character” seal used by the factory during this time period.

In the images below, let us examine several helmet lid pots with varying seals and workmanship. In the period between the late Qing to the early years of Factory #1, the most obvious distinguishing aspects are in the seals and the workmanship (the clay and firing are also different, as we will discuss later). Pay close attention to the differences in workmanship, especially how the pot base is joined to the body, the lid wall to the lid, and the overall detailing. Examining again the workmanship of the Factory #1 teapots, the difference between fully handmade construction and those made using molds should be readily apparent.

Based on the seals and workmanship observed, readers who are familiar with factory style pots, should be able to quickly identify the pots that fulfil the characteristics of Factory #1 pots of the ‘60s. But for pots made before the establishment Factory #1, due to the many different workshops in existence, there’s a much broader range in terms of the seals used, as well as the workmanship. If you compare them to early Factory #1 pots, you may realize that some of these early ROC pots are actually the prototype that early Factory #1 molds are based on. So, the lineage can clearly be traced to this point of origin.

The clay and firing of helmet lids

From the following pictures we can realize that most of the helmet lids were made using hongtu (紅土; hóngtǔ; red clay); although zisha items are common in the late Qing to ROC period, “standard” style shuiping pots in this era are rarely made from zisha. Apart from the predominant use of hongtu, some of the higher end pots are made of zhuni, (refer to figure 15 and 16). In particular, pay attention to the pot in figure 15, with the base seal Yixing Hui Meng Chen, on the inside of the lid, you can see the lid wall is beveled inwards, similar to that of the Xi Sheng pot in figure 4. Both the material and the workmanship are exemplars of that period and quite rare.

About the firing, pots before the 1960s are mainly fired in a “dragon kiln”. After the 60s, the “downdraft kiln” was predominantly used instead. Both kilns have a huge firing space, which take longer time to heat up and cool down, and difficult to control the temperature. Especially the dragon kiln, firing temperature is hard to control, some with higher temperature will turn the red clay into a strong redness, whilst in some area of the kiln where the temperature is lower, the red clay may appears orange red. There is marked differences between pots that are fired in the same batch. After the use of the downdraft kiln in 1960s, although there are some rare instances of under or over firing, the temperature is much more consistent, resulting in higher quality of production with homogenous firing and color.

Identification of “Helmet Lid” Teapots

With the increased popularity in Yixing pot collecting in the 1980s in Taiwan, the helmet lid received recognition, and was highly sought after, as such, with demand, such pots cannot escape from being replicated and forged. To the new collectors today, should not judge a pot by simply how puffed the lid looks, one will need to consider many other factors mentioned below to achieve better validation.

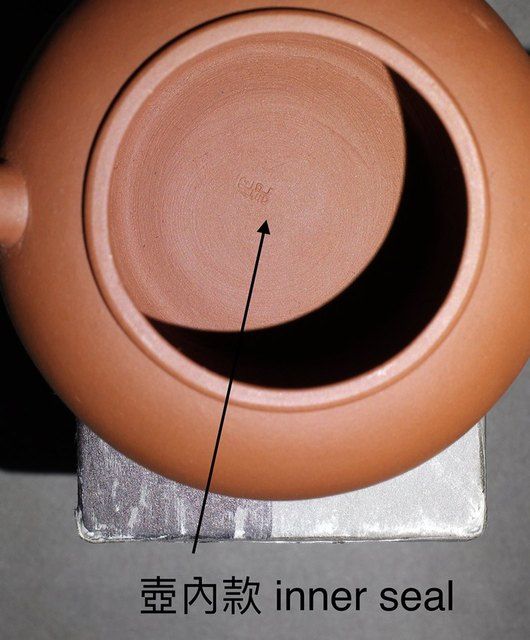

I. The seal

In early-period teapots, the helmet lid appeared between late-Qing- early-ROC to the early 1960s. Due to the many different private workshops in the early days and the establishment of Factory #1 at the end of this era, although we had not been able to cover 100% of all the seals used in this era, the pictures shown would have covered majority of the commonly seen seals of the helmet lid pots. These pictures can serve as a basis for comparison for the collectors. Although seals can be forged, its not easy to achieve 100% replication in details, especially when seals from the Early ROC are very unique and have their own characteristics. Despite this, the pot seal can be useful as a first step in pot authentication.

II. Workmanship

In these photos, please pay special attention to the knob, the inner details of the lid, and to the way the pot base is joined to the body. If the seal is one that is used before Factory #1 was established, the workmanship of the pot should be handmade with hand joinin. If the seal is post Factory #1, the pot should show signs of the use of molds with hand-detailing. From the Qing to ROC eras, the workmanship tends to be either very refined and delicate, or else very rough. After Factory #1 was established, pots became intermediate, neither very refined nor very rough, following a very systematic standard. ,

III. Clay and Firing Temperature

As described earlier, most helmet lid pots are made of red clay, fired either in the dragon kiln (龍窯; lóngyáo) or later in the downdraft kiln. Because of differences in temperature control, the color of the pot body can vary a lot; at the same time due to the handmade workmanship and firing temperature, evidence of shrinkage is more obvious, that you can observe as wavy patterns at certain angles under light, or traces of handmade construction, such as in figure 17 and 18. Different firing methods from the dragon kilns, to downdraft kilns, to modern push board or gas kilns, will affect the appearance of the fired-clay. Early-period teapots, when new and unused, generally look a bit flat in tone and slightly sandy; this is even so for zhuni pots — they will never be dead glossy or oily glossy, but in the glossiness there is a plain sandy feel. Pots from modern firing have a clear glazed, glassy bright feel. Examining more pots in person should help you develop a sense of these differences.

New pot collectors, based on the aspects described previously, may feel that the differences described are not large and difficult to distinguish. But if you start doing comparison using multiple aspects all at once to assess a pot, you will start to discern for yourself. The best way to learn is to handle the pot in person; there is no way around this. It is better to ask lots of questions, and handle lots of pots, rather than to rush into buying. Find a reliable vendor or merchant, and buy one good pot to use, and experience the shape, workmanship, and material at your leisure, after some time, then one will start to understand.

In summary, the development of Yixing teapots is systematic, and can be classified. Depending on various reasons and fates, the social and cultural background of the different periods etc, this will show up in the workmanship. Early-period teapots can be classified into different groupings, because within these groups they carry along with them a set of characteristics. Different eras will produce different types of pots, and pots exhibiting a mix of characteristics from different eras must be fake.

The “helmet lid” period represents the period in Yixing zisha development in which we see a shift from a diversity of styles to a more standard expression after the establishment of factory #1. We can see in these pots the diversity and artistic expressions in the late Qing to ROC period, and the standardization after Factory #1 was established, whether on the shape, workmanship, seal, material. Pots from this era, have become representative, and the ability to own a single piece, to most collectors, one is very fortunate indeed.

(Thanks the help of Kyara Zen and William Yardley in translation and proofreading.)

Chapter 2 The “Helmet Lid” (“Puffed Lid”) Teapot Series

(draft version)

(鋼盔蓋(椪蓋)系列英文版初稿)

(Please match this article with the content of P.18 to 25 of my book to read.)

After the establishment of Yixing Factory #1, all pots are produced in a very systematic way, and there is plenty of evidence for us to trace. Pots made during different time periods and in different environments will show characteristics of these periods. These characteristics and systems are not only important tools of us to grasp early-period teapots but also represent some part of Yixing zisha history.

The early-period teapots express the phrase “from diversity to unity”. If we want to fully understand this development and importance, we need to pay attention to the earliest examples of early-period teapots, the “helmet lid” / “puffed lid” series.

What we call “helmet lid” (鋼盔蓋; gāngkuī gài; steel helmet lid) or “puffed lid” (椪蓋; pèng gài), refers to the shape of the pot lid, where the curve from the edge of lid towards the knob rises more sharply, resulting in a more convex shape, reminiscent of a military helmet. Figures 1 and 2, show the differences in shape between the helmet lid and the regular 1970s shuiping teapot lid. The helmet lid looks as though it is half of a sphere, whilst the 70s lid is generally flatter. The lid is not the only unique attribute of this series; rather, the “helmet lid” series has other important differences from other early-period teapots, including age, workmanship, clay, firing and era meanings. We will discuss these attributes in the following paragraphs.

If we want to explain the period of the helmet lid, we need to first understand how pot lids are made. Early-period teapot lids were made in two different way. The first method involved putting a piece of flattened clay into a steel or plaster mold, and pressing to form the basic shape, then detailing by hand. The earlier the pot was produced, the less prevalent the use of molds, so the signs of handmade workmanship are more obvious. For example, the method of joining the lid wall to the lid by hand is a method inherited from Qing in the early ROC period, until the end of the 1950s, where the lid walls were made by mold together with lid, (see p.514 for reference). In the second method, the lids were completely handmade. Regardless of the method used, the curvature of the lid is determined by the shape and curvature of the mold, which, in turn, was determined by the aesthetics and common practice of ceramic artists during that era. As such, the curvature of the lid evolved over time.

Let us start by examining a zhuni (朱泥; zhūní; vermillion) shuiping pot made in the late Qing / early ROC era, stamped with the Xi Sheng (熙生; xīshēng) seal (refer to figure 3). This is an authentic piece of Qing to ROC handmade shuiping pot, not only is the clay texture very delicate, but the workmanship is also very detailed. The lid walls, instead of being rounded, are beveled inwards, a mark of a pot made by a master craftsman. This pot shape and workmanship is similarly seen in works by other famous Qing potters, e.g., Chang Ji (昌記; Chāng Jì), Yuan Yi He (袁義和; Yuán Yì hé), so we can conclude that many of the shuiping pots with similar marks can classified as the platonic ideal of a shuiping pot. From the shape of the lid of this pot, we can see that during the late Qing period, the standard style for shuiping lids is the rotund “helmet lid”. This style was the standard through early ROC, even the early years of Factory #1 in the late ‘50s. We can still find examples of this style in the early ‘60s, but in much smaller quantities. In figure 4, you can see a 1960s six cup shuiping pot; the base seal is 6 characters, and the inner base seal is Ting Ji (庭記; tíng jì), this represents the last appearances of the helmet lid in Factory #1. (Note: not all of the Ting Ji pots have helmet lids). After the mid ‘60s, due to new molds, the helmet lids were replaced with flatter lids, and as such, the helmet lid style became more or less extinct after that time.

Why were the molds changed from the “helmet lid” shape to the comparatively flatter design? It could be due to the emphasis on productivity and high volume during that time period, because the helmet lids were harder to remove from a mold than the flatter ones were, or it could simply be a change in style / aesthetics. However, this shape only appeared between the end of the Qing period to the early ‘60s. This characteristic was not seen in pots from the later years. As we discuss the helmet lid teapots, this term refers not just to the shape of the lid, but also to a specific era.

The seals and workmanship of helmet lid pots

From the seals and workmanship of helmet lid pots, we have now identified that this characteristic spans the late Qing to the early 1960s. Within this timeline, there is a very important landmark — the establishment of Factory #1. Before Yixing Zisha Factory #1 was established, pots were mostly made in private workshops by artisans; the seals used were diverse, the pots were largely handmade — the seam of the lid wall, the body, the spout, and the handle were mostly handmade. In contrast, after the establishment of Yixing Factory #1, because of the shift towards mass production, previously handmade parts were now also shaped by molds; most items were initially formed using molds, and then finished by hand. Naturally, the pots produced after the establishment of Factory #1 used the standard “6 character” seal used by the factory during this time period.

In the images below, let us examine several helmet lid pots with varying seals and workmanship. In the period between the late Qing to the early years of Factory #1, the most obvious distinguishing aspects are in the seals and the workmanship (the clay and firing are also different, as we will discuss later). Pay close attention to the differences in workmanship, especially how the pot base is joined to the body, the lid wall to the lid, and the overall detailing. Examining again the workmanship of the Factory #1 teapots, the difference between fully handmade construction and those made using molds should be readily apparent.

Based on the seals and workmanship observed, readers who are familiar with factory style pots, should be able to quickly identify the pots that fulfil the characteristics of Factory #1 pots of the ‘60s. But for pots made before the establishment Factory #1, due to the many different workshops in existence, there’s a much broader range in terms of the seals used, as well as the workmanship. If you compare them to early Factory #1 pots, you may realize that some of these early ROC pots are actually the prototype that early Factory #1 molds are based on. So, the lineage can clearly be traced to this point of origin.

The clay and firing of helmet lids

From the following pictures we can realize that most of the helmet lids were made using hongtu (紅土; hóngtǔ; red clay); although zisha items are common in the late Qing to ROC period, “standard” style shuiping pots in this era are rarely made from zisha. Apart from the predominant use of hongtu, some of the higher end pots are made of zhuni, (refer to figure 15 and 16). In particular, pay attention to the pot in figure 15, with the base seal Yixing Hui Meng Chen, on the inside of the lid, you can see the lid wall is beveled inwards, similar to that of the Xi Sheng pot in figure 4. Both the material and the workmanship are exemplars of that period and quite rare.

About the firing, pots before the 1960s are mainly fired in a “dragon kiln”. After the 60s, the “downdraft kiln” was predominantly used instead. Both kilns have a huge firing space, which take longer time to heat up and cool down, and difficult to control the temperature. Especially the dragon kiln, firing temperature is hard to control, some with higher temperature will turn the red clay into a strong redness, whilst in some area of the kiln where the temperature is lower, the red clay may appears orange red. There is marked differences between pots that are fired in the same batch. After the use of the downdraft kiln in 1960s, although there are some rare instances of under or over firing, the temperature is much more consistent, resulting in higher quality of production with homogenous firing and color.

Identification of “Helmet Lid” Teapots

With the increased popularity in Yixing pot collecting in the 1980s in Taiwan, the helmet lid received recognition, and was highly sought after, as such, with demand, such pots cannot escape from being replicated and forged. To the new collectors today, should not judge a pot by simply how puffed the lid looks, one will need to consider many other factors mentioned below to achieve better validation.

I. The seal

In early-period teapots, the helmet lid appeared between late-Qing- early-ROC to the early 1960s. Due to the many different private workshops in the early days and the establishment of Factory #1 at the end of this era, although we had not been able to cover 100% of all the seals used in this era, the pictures shown would have covered majority of the commonly seen seals of the helmet lid pots. These pictures can serve as a basis for comparison for the collectors. Although seals can be forged, its not easy to achieve 100% replication in details, especially when seals from the Early ROC are very unique and have their own characteristics. Despite this, the pot seal can be useful as a first step in pot authentication.

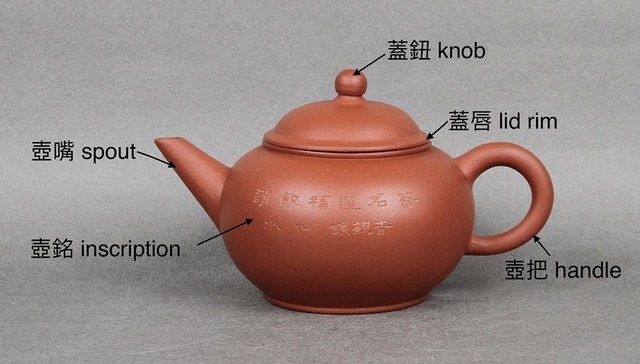

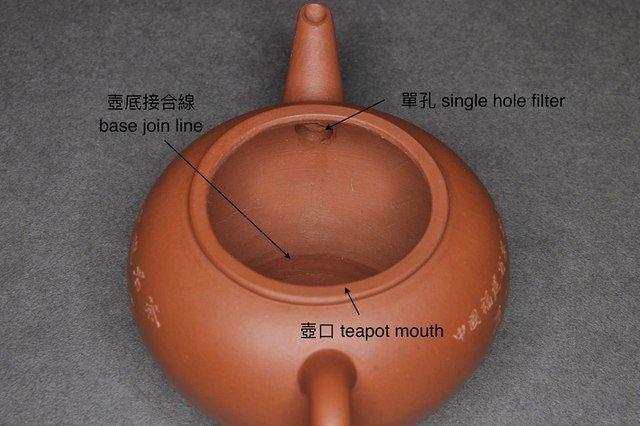

II. Workmanship

In these photos, please pay special attention to the knob, the inner details of the lid, and to the way the pot base is joined to the body. If the seal is one that is used before Factory #1 was established, the workmanship of the pot should be handmade with hand joinin. If the seal is post Factory #1, the pot should show signs of the use of molds with hand-detailing. From the Qing to ROC eras, the workmanship tends to be either very refined and delicate, or else very rough. After Factory #1 was established, pots became intermediate, neither very refined nor very rough, following a very systematic standard. ,

III. Clay and Firing Temperature

As described earlier, most helmet lid pots are made of red clay, fired either in the dragon kiln (龍窯; lóngyáo) or later in the downdraft kiln. Because of differences in temperature control, the color of the pot body can vary a lot; at the same time due to the handmade workmanship and firing temperature, evidence of shrinkage is more obvious, that you can observe as wavy patterns at certain angles under light, or traces of handmade construction, such as in figure 17 and 18. Different firing methods from the dragon kilns, to downdraft kilns, to modern push board or gas kilns, will affect the appearance of the fired-clay. Early-period teapots, when new and unused, generally look a bit flat in tone and slightly sandy; this is even so for zhuni pots — they will never be dead glossy or oily glossy, but in the glossiness there is a plain sandy feel. Pots from modern firing have a clear glazed, glassy bright feel. Examining more pots in person should help you develop a sense of these differences.

New pot collectors, based on the aspects described previously, may feel that the differences described are not large and difficult to distinguish. But if you start doing comparison using multiple aspects all at once to assess a pot, you will start to discern for yourself. The best way to learn is to handle the pot in person; there is no way around this. It is better to ask lots of questions, and handle lots of pots, rather than to rush into buying. Find a reliable vendor or merchant, and buy one good pot to use, and experience the shape, workmanship, and material at your leisure, after some time, then one will start to understand.

In summary, the development of Yixing teapots is systematic, and can be classified. Depending on various reasons and fates, the social and cultural background of the different periods etc, this will show up in the workmanship. Early-period teapots can be classified into different groupings, because within these groups they carry along with them a set of characteristics. Different eras will produce different types of pots, and pots exhibiting a mix of characteristics from different eras must be fake.

The “helmet lid” period represents the period in Yixing zisha development in which we see a shift from a diversity of styles to a more standard expression after the establishment of factory #1. We can see in these pots the diversity and artistic expressions in the late Qing to ROC period, and the standardization after Factory #1 was established, whether on the shape, workmanship, seal, material. Pots from this era, have become representative, and the ability to own a single piece, to most collectors, one is very fortunate indeed.

(Thanks the help of Kyara Zen and William Yardley in translation and proofreading.)

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

Chapter 3 The series of “Lid with number of cups seal”

----

(The draft version. Any comment, including English translation is welcome. Thank you. )

(Please match this article with the content of P.70 to 76 of the book to read.)

----

Tea lovers in Taiwan generally will keep several early-period teapots, they like the match of old pots with aged teas, which can create an admiringly reminiscent atmospheres. Early-period teapot represents not only an era of China Yixing purple clay history, but also a period where standardization was established, and on that foundation, diversity was developed. It is as important as the “Label”(印級) Pu’er tea and the 70s’ Qi Zhi bing cha (七子餅茶) to pu’er tea, which standardized the manufacturing methods from late Qing dynasty to early ROC and becoming a classical standards and references of their following products. Especially the teapots which were developed in 60s are considered as the successors and pioneers of the Yixing teapots, and if someone would like to understand the development of Yixing purple clay art, Early-period teapots will play an important role and shouldn’t be ignored.

In the 1950s, in an attempt to revive the purple clay industry in China, the Tang Du Ceramic Production Cooperation Purple Clay Factory (湯渡陶業生產合作社紫砂工場)and Yixing Purple Clay Art Factory (宜興紫砂工藝廠, also known as Factory # 1) led by Gu Jing Zhou, Wang Yin Chun, Zhu Ke Xin, Wu Yun Gen as directors were founded. On one hand, recruiting some apprentices, on the other, crafting different pot shapes and developing new methods and equipment to enhance productivity, for example, spinning machine and plaster molds. In the 1950s, due to the “Great Leap Forward”, the market supply still far exceeded the demand. Until early 1960s, the production volume started slowly increase, and the production scale of the

Early-period teapots was established approximate at this time.

In the early years of Yixing Factory #1 the various type of pots was standardized, this leaded to appear a batch of teapots with “number of cups seal” stamped inside of the lid. In order to enhance productivity and make standardization, producer set the shape and size for various types of pots and stamped the size or the pot’s name inside of the lid to annotate it. The stamping of the cup size inside of the lid is done in a similar way as the pot name, which you will see later in the later chapter of “Appreciation of the Five Shapes Serious(五形壺)”. Occasionally, Factory # 1 stamped both the name and size inside the lid, refer to figure 1, you can see both the name “Xian Piao”(線漂) and the size “6 Cup”(六杯) were stamped.

Most of this single/double stamping of cup size and name inside the lid occurred during the early years of Factory # 1. So the pots with the number seal inside the lid is recognized as mark of the early years products of Factory # 1, the base seal of the pots are matched with 6 character seals, i.e. Jing Xi Hui Meng Chen(荊溪惠孟臣製), Jing Xi Nan Meng Chen(荊溪南孟臣製) and Yixing Hui Meng Chen(宜興惠孟臣製), there will never be a Zhong Guo Yixing(中國宜興) Seal because the Zhong Guo Yixing Seal only came at the end of the 1960s. So if one find a pot with both the base seal as Zhong Guo Yixing and the lid having the number of cups, you should be cautious!

Based on current research, the “number of cup seal” including 4 Cup(四杯), 5 cups(五杯), 6 Cups(六杯), 8 Cups(八杯), and 12 cups(十二杯) , match with size about 60cc, 70cc, 75cc, 105cc and 150cc respectively. The 6 cup and 12 cup seals are the most common, whilst 4, 5, and 8 cup seals are rarer. One of things that we curious about is whether there is existing 10 cup seal or not. We have never found any one so far, but believe it to possibly exist, except being very rare.

At this point of time it is important to clarify the difference between cup size in Taiwan and in China. What the Taiwanese refer to as 4 cup, in actual fact is the Chinese 6 cup, and the Taiwanese 8cup will be the Chinese 12 cup seal. It’s being premised on the Taiwanese collectors are mostly exposed to pots from the 1970s onwards, in the 70s, Factory # 1 pots do not have number of cups seal stamped in the lids, so Taiwanese collectors decided to define their own cup size by referencing to the size of cups that are used in Taiwanese Gong-Fu tea.

This is how the sizes of 2 to 8 cup in Taiwan came about, and results in the discrepancy with Factory # 1’s cup size.

Many readers would be most concerned with being able to recognize and validate these pots at the moment. Let us describe some of the special traits of these pots. As these pots are made in the early 1960s, it should have the traits of ‘60s in clay, workmanship, shape, seal and firing. In clay, these pots should satisfy the standard of the clay fineness and tenderness of the 60s, the color slightly powder with flat gloss and delicate texture, sometimes can see some fine yellow grains on the surface. If the coloration looks too bright red or shiny glow, similar as “Zhuni”, these pots may be questionable. After Yixing Factory # 1 was established, it was production-oriented not exquisite-oriented, so they wasn’t spend too much time on making fragile and high failure Zhuni pots. This is basic knowledge about Early-period teapots, and if someone tells you he has a 60s’ Zhuni pot, it goes to show some questions to pot.

As for workmanship and shape, when plaster molds have been created to assist production, the standard workflow dictate to use the mold to create the basic shape before touch up of potters. In the whole history of Yixing Factory # 1, in order to increase output, the creation and use of molds evolved with the eras. If we observe the shape and workmanship of teapots from ’60s to ‘90s, we can find this important feature. The earlier the pot is, the more hand touch up/hand correcting traits, the more recent the pot is, the less of these traits.

This is not a matter of “exquisite” or “coarse”, but some parts, such as the inside of the lid and knob, due to the use of different advanced molds, will not need correction or if need be, uses a different way of correcting. So when we talk about the workmanship, we have to look at the whole pot and the overall workmanship and methods used instead of single special trait, from figure 2 to 8 are various examples of pots with the number of cups stamped on the lid. You may realize that pots with the cup stamped on the lid, it all can be found with base seal of Yixing Hui(宜興惠), Da Xi(大溪), Xiao Xi(小溪), Nan Mengchen(南孟臣), there’s no any special relationship between cup size and base seal. Apart from the ordinary shuiping pot, there are some special ones, i.e. in figure 9, where there is a Ting Ji(庭記) seal on the inside of the pot, in figure 10, 11, 12, are Gao Jian Fa Tea merchant(高泉發茶行), figure 13, Please Drink Fujian Famous tea(請飲福建名茶) , figure 14, Shan Juan Dong Commemoration(善卷洞留念) with 5 cup seal etc. Readers can compare the clay, workmanship, shape, and base seals of these pots to see if they all agree with what we have described about the traits earlier on.

After discussed the “authentic”, we have to discuss the “fake” too. As pots with the number of cup seal inside the lids are considerably rare and sought after, there are many replicas on the markets, and these counterfeit pots bear the similar lid seal, and similar 6 character base seals. For the first look, these pots may look similar and possibly authentic, but if you look in detail, there exists many aspects that are not consistent with ‘60s traits, including the clay, the workmanship, the type of molds used and the workmanship of lid, especially the base seal has significant difference. Figure 15 is a classical duplicated Yixing Hui Mengchen with 12 cup lid seal in ‘90s, we can compare it with the previous authentic Yixing Hui Mengchen figures in this chapter to see the difference.

Briefly, the lid with number of cups seal was a meaningful mark in Chinese purple clay development history. These pots not only represent the history and development of Yixing Factory # 1, they also represent a specific eras, the early 1960s. When we appreciate or identify such a series of pots, we need to insist on the “system of eras” of Early-period pots, different era should have different traits. Except the lid seal, the series of “Lid with number of cups seal” should be the same with the other ‘60s in every trait, including the clay, workmanship, shape, base seal and firing. This was called the “system of eras” of Early-period teapots.

The clay, molds and the potters are all similar! The quantity of Early-period teapots is rare and collectors are numerous. Newcomers should compare more, touch more, study more and shut his ears to stories about pots. Once you embark on the wrong path, you will go awry in pot collecting.

(Thanks the help of Kyara Zen and the other foreign fiend in translation and proofreading.)

----

(The draft version. Any comment, including English translation is welcome. Thank you. )

(Please match this article with the content of P.70 to 76 of the book to read.)

----

Tea lovers in Taiwan generally will keep several early-period teapots, they like the match of old pots with aged teas, which can create an admiringly reminiscent atmospheres. Early-period teapot represents not only an era of China Yixing purple clay history, but also a period where standardization was established, and on that foundation, diversity was developed. It is as important as the “Label”(印級) Pu’er tea and the 70s’ Qi Zhi bing cha (七子餅茶) to pu’er tea, which standardized the manufacturing methods from late Qing dynasty to early ROC and becoming a classical standards and references of their following products. Especially the teapots which were developed in 60s are considered as the successors and pioneers of the Yixing teapots, and if someone would like to understand the development of Yixing purple clay art, Early-period teapots will play an important role and shouldn’t be ignored.

In the 1950s, in an attempt to revive the purple clay industry in China, the Tang Du Ceramic Production Cooperation Purple Clay Factory (湯渡陶業生產合作社紫砂工場)and Yixing Purple Clay Art Factory (宜興紫砂工藝廠, also known as Factory # 1) led by Gu Jing Zhou, Wang Yin Chun, Zhu Ke Xin, Wu Yun Gen as directors were founded. On one hand, recruiting some apprentices, on the other, crafting different pot shapes and developing new methods and equipment to enhance productivity, for example, spinning machine and plaster molds. In the 1950s, due to the “Great Leap Forward”, the market supply still far exceeded the demand. Until early 1960s, the production volume started slowly increase, and the production scale of the

Early-period teapots was established approximate at this time.

In the early years of Yixing Factory #1 the various type of pots was standardized, this leaded to appear a batch of teapots with “number of cups seal” stamped inside of the lid. In order to enhance productivity and make standardization, producer set the shape and size for various types of pots and stamped the size or the pot’s name inside of the lid to annotate it. The stamping of the cup size inside of the lid is done in a similar way as the pot name, which you will see later in the later chapter of “Appreciation of the Five Shapes Serious(五形壺)”. Occasionally, Factory # 1 stamped both the name and size inside the lid, refer to figure 1, you can see both the name “Xian Piao”(線漂) and the size “6 Cup”(六杯) were stamped.

Most of this single/double stamping of cup size and name inside the lid occurred during the early years of Factory # 1. So the pots with the number seal inside the lid is recognized as mark of the early years products of Factory # 1, the base seal of the pots are matched with 6 character seals, i.e. Jing Xi Hui Meng Chen(荊溪惠孟臣製), Jing Xi Nan Meng Chen(荊溪南孟臣製) and Yixing Hui Meng Chen(宜興惠孟臣製), there will never be a Zhong Guo Yixing(中國宜興) Seal because the Zhong Guo Yixing Seal only came at the end of the 1960s. So if one find a pot with both the base seal as Zhong Guo Yixing and the lid having the number of cups, you should be cautious!

Based on current research, the “number of cup seal” including 4 Cup(四杯), 5 cups(五杯), 6 Cups(六杯), 8 Cups(八杯), and 12 cups(十二杯) , match with size about 60cc, 70cc, 75cc, 105cc and 150cc respectively. The 6 cup and 12 cup seals are the most common, whilst 4, 5, and 8 cup seals are rarer. One of things that we curious about is whether there is existing 10 cup seal or not. We have never found any one so far, but believe it to possibly exist, except being very rare.

At this point of time it is important to clarify the difference between cup size in Taiwan and in China. What the Taiwanese refer to as 4 cup, in actual fact is the Chinese 6 cup, and the Taiwanese 8cup will be the Chinese 12 cup seal. It’s being premised on the Taiwanese collectors are mostly exposed to pots from the 1970s onwards, in the 70s, Factory # 1 pots do not have number of cups seal stamped in the lids, so Taiwanese collectors decided to define their own cup size by referencing to the size of cups that are used in Taiwanese Gong-Fu tea.

This is how the sizes of 2 to 8 cup in Taiwan came about, and results in the discrepancy with Factory # 1’s cup size.

Many readers would be most concerned with being able to recognize and validate these pots at the moment. Let us describe some of the special traits of these pots. As these pots are made in the early 1960s, it should have the traits of ‘60s in clay, workmanship, shape, seal and firing. In clay, these pots should satisfy the standard of the clay fineness and tenderness of the 60s, the color slightly powder with flat gloss and delicate texture, sometimes can see some fine yellow grains on the surface. If the coloration looks too bright red or shiny glow, similar as “Zhuni”, these pots may be questionable. After Yixing Factory # 1 was established, it was production-oriented not exquisite-oriented, so they wasn’t spend too much time on making fragile and high failure Zhuni pots. This is basic knowledge about Early-period teapots, and if someone tells you he has a 60s’ Zhuni pot, it goes to show some questions to pot.

As for workmanship and shape, when plaster molds have been created to assist production, the standard workflow dictate to use the mold to create the basic shape before touch up of potters. In the whole history of Yixing Factory # 1, in order to increase output, the creation and use of molds evolved with the eras. If we observe the shape and workmanship of teapots from ’60s to ‘90s, we can find this important feature. The earlier the pot is, the more hand touch up/hand correcting traits, the more recent the pot is, the less of these traits.

This is not a matter of “exquisite” or “coarse”, but some parts, such as the inside of the lid and knob, due to the use of different advanced molds, will not need correction or if need be, uses a different way of correcting. So when we talk about the workmanship, we have to look at the whole pot and the overall workmanship and methods used instead of single special trait, from figure 2 to 8 are various examples of pots with the number of cups stamped on the lid. You may realize that pots with the cup stamped on the lid, it all can be found with base seal of Yixing Hui(宜興惠), Da Xi(大溪), Xiao Xi(小溪), Nan Mengchen(南孟臣), there’s no any special relationship between cup size and base seal. Apart from the ordinary shuiping pot, there are some special ones, i.e. in figure 9, where there is a Ting Ji(庭記) seal on the inside of the pot, in figure 10, 11, 12, are Gao Jian Fa Tea merchant(高泉發茶行), figure 13, Please Drink Fujian Famous tea(請飲福建名茶) , figure 14, Shan Juan Dong Commemoration(善卷洞留念) with 5 cup seal etc. Readers can compare the clay, workmanship, shape, and base seals of these pots to see if they all agree with what we have described about the traits earlier on.

After discussed the “authentic”, we have to discuss the “fake” too. As pots with the number of cup seal inside the lids are considerably rare and sought after, there are many replicas on the markets, and these counterfeit pots bear the similar lid seal, and similar 6 character base seals. For the first look, these pots may look similar and possibly authentic, but if you look in detail, there exists many aspects that are not consistent with ‘60s traits, including the clay, the workmanship, the type of molds used and the workmanship of lid, especially the base seal has significant difference. Figure 15 is a classical duplicated Yixing Hui Mengchen with 12 cup lid seal in ‘90s, we can compare it with the previous authentic Yixing Hui Mengchen figures in this chapter to see the difference.

Briefly, the lid with number of cups seal was a meaningful mark in Chinese purple clay development history. These pots not only represent the history and development of Yixing Factory # 1, they also represent a specific eras, the early 1960s. When we appreciate or identify such a series of pots, we need to insist on the “system of eras” of Early-period pots, different era should have different traits. Except the lid seal, the series of “Lid with number of cups seal” should be the same with the other ‘60s in every trait, including the clay, workmanship, shape, base seal and firing. This was called the “system of eras” of Early-period teapots.

The clay, molds and the potters are all similar! The quantity of Early-period teapots is rare and collectors are numerous. Newcomers should compare more, touch more, study more and shut his ears to stories about pots. Once you embark on the wrong path, you will go awry in pot collecting.

(Thanks the help of Kyara Zen and the other foreign fiend in translation and proofreading.)

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

Thank you, kyarazen for all your efforts to bring yixing knowledge to the western world! So much good info!

Apr 8th, '17, 14:17

Posts: 813

Joined: Nov 13th, '12, 13:49

Location: santa monica, california, usa

Contact:

victoria3

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

Thanks so much. I ordered the book. This will really come in handy.

Apr 8th, '17, 14:48

Posts: 813

Joined: Nov 13th, '12, 13:49

Location: santa monica, california, usa

Contact:

victoria3

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

Can you provide link?JB-ONE wrote: Thanks so much. I ordered the book. This will really come in handy.

Apr 8th, '17, 15:11

Posts: 1144

Joined: Jul 10th, '13, 01:38

Scrolling: scrolling

Location: Japan.

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

Yeah, it would be much appreciated! Thanks JB!

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

Apr 8th, '17, 17:50

Posts: 1144

Joined: Jul 10th, '13, 01:38

Scrolling: scrolling

Location: Japan.

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

That's a smart move, thanks for the tip!JB-ONE wrote:I contacted Dr Lu through his fb

https://m.facebook.com/groups/142937832 ... 0127834129

Apr 8th, '17, 18:08

Posts: 813

Joined: Nov 13th, '12, 13:49

Location: santa monica, california, usa

Contact:

victoria3

Re: Translated Articles from Early Teapots Volume 2 早期壶事典-貳

I've been following his fb page for a while also. Are you saying you requested English book via his facebook ?William wrote:That's a smart move, thanks for the tip!JB-ONE wrote:I contacted Dr Lu through his fb

https://m.facebook.com/groups/142937832 ... 0127834129